Category : MACHINES

By Diego Pinochet(Chile)

The use of technology in architectural design, by being focused mainly on the -both digital and physical - of a pre-determined idea, has neglected many of the implications of using digital tools in a more explorative way by integrating body and senses in the design processes.

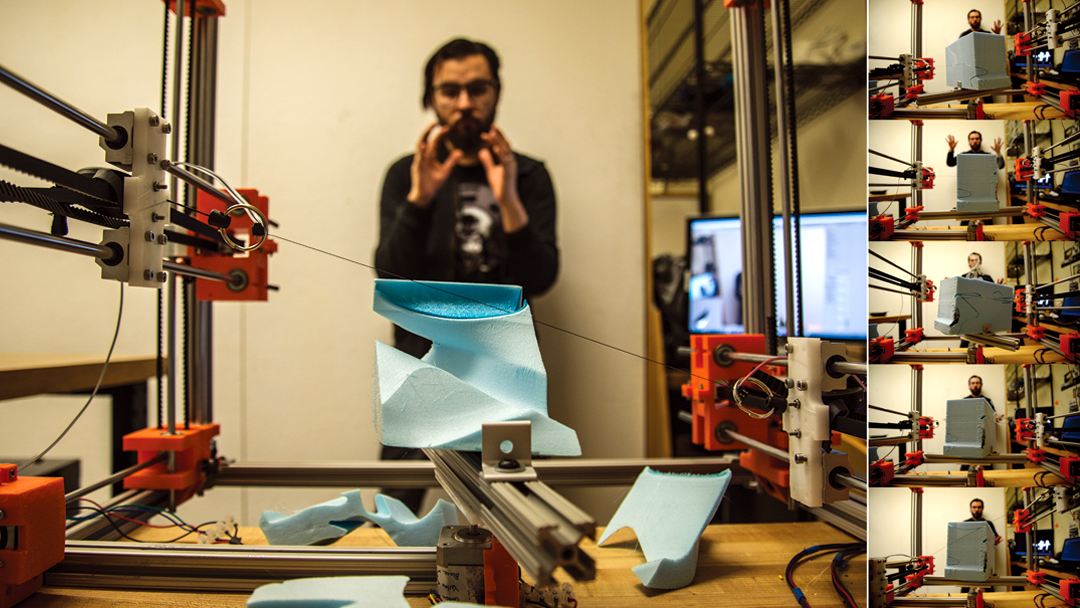

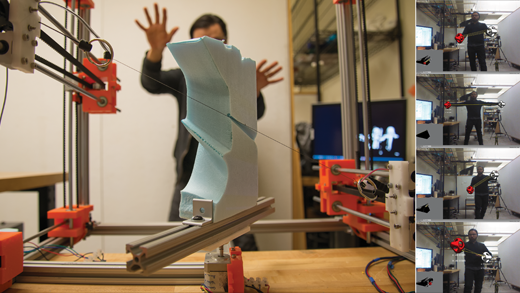

'Making Gestures’ proposes a model of interaction that seeks to transcend the hylomorphic model imperative in today’s architectural design practice to a more reciprocal form of computational making. To do so, it explores real-time interaction between mind, body, and design tools by using body gestures and imbuing fabrication machines with behavior using artificial intelligence in order to establish a dialog which embraces ambiguity and the unexpected to engage architects into insightful design and fabrication processes.

[About the Fab Machine]

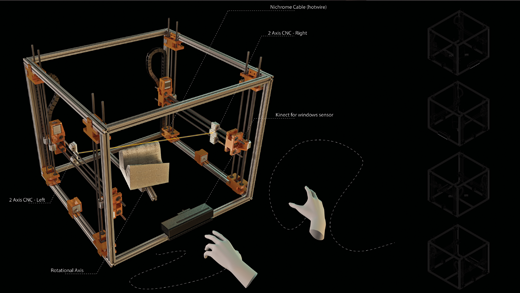

‘Making Gestures: a personal fabrication and deign system' is proposed to explore real-time interaction between mind, body, and tools by using body gestures and imbuing fabrication machines with artificial intelligence. It's A 5-axis CNC machine developed and programmed using machine learning algorithms, in order to learn and adapt to the uniqueness of the user. 'Making Gestures' is a cybernetic system that allows to design and make in real time, adapting 'as you go'.

MAKING_GESTURES_DPINOCHET from DIGIFAB on Vimeo.

Luke Yeung

Luke Yeung

The project shows us the exciting possibilities that designing new tools can have. It takes on the challenge of human and computer interaction design by looking into the artist’s realms – particularly sculpture and hand-craft – as ways to create new instruments to enhance human creativity. The example shown currently makes use of low-density foam, but it is not difficult to imagine other materials - wood or stone for instance – as the medium in future iterations. From this point of view the project is an exciting example of designing a tool that has the potential to make a profound impact on design, fabrication and construction in the future.

Seiichi Saito

Seiichi Saito

Regardless of how reasonable and accessible 3D design has become, the fact remains that it is still difficult to access for the masses. I was impressed with the fact that this entry is designed to make the ‘making process’ easier and more instinctive. It also places the spotlight on the evolution of tools such as software so that more people can have access to a greater variety of creative methods in the future.

Yukiko Shikata

Yukiko Shikata

In the video, the person who is cutting the polystyrene foam with gentle gestures has a meditative expression on his face almost like he is doing Qigong breathing exercises. When inputting data, this system makes it possible to proactively adopt intuition and ambiguity which are normally illuminated from the process. Although AI is integrated, we can now incorporate unpredictable noises including own individual physical traits into our objects of creation. This enables the creation of forms that have never been possible before, in various fields such as in sculpture, architecture, performance, but more importantly it strikes a critical balance between predicting the impossible and controlling the possible. The work demonstrates a playful and crazy hacking spirit that ventures into the realm of unknown.

Hiroya Tanaka

Hiroya Tanaka

In our FabLab, which has been around for a decade now, we are seeing a rapid shift over to what we call Fab2.0.

In a nutshell, Fab1.0 refers to when we make things with the regular digital fabrication tools (like laser cutters and 3D printers) that you can buy in the stores, but the truth is these tools have their limitations. To that end, we have moved on to what we call Fab2.0 which is where we hack these original machines, and take our activities out of the box. Centuries ago, craftsman and artists not only created their masterpieces, but also had to craft their own tools and materials. And with the Fab movement, this is exactly what we are experiencing now.

I think this project, which uses a process of trial and error to make a machine that is tailormade to their needs and draws on existing technology, is an ideal reflection of the direction in which the Fab movement is heading globally and it epitomizes Fab2.0.

Luki Huber

Luki Huber

It is easy to forget about manual labor in this virtual era. When we touch something we are able to understand it. This is why it is extremely important to keep making hand-made prototypes. The idea of combining manual and virtual labor is also a highly interesting approach. In this case, a human being becomes a sort of orchestra conductor for a machine. A great piece.

Quake Hsu

Quake Hsu

‘Making Gestures’ is a magical machine probably every Fabber has ever dreamed. Although the maker behind this project aimed to create a new design tool focusing on architectural work, I could see this technology being applied to many other creative fields. Nowadays, designers rely on computer-aid-design technology to draw and present their ideas. The convenience and precision of CAD make designers avoid the errors, but somehow eliminate the uncertainty too. The uncertainty is for sure the fun factor of design process. ‘Making Gestures’ for me is taking creators back to the age full of surprises and once again we should enjoy the control of creative process through our body and muscle.