Category : GENERAL

By Yoshisuke Kuramoto (Japan)

It became difficult for me to walk due to a traffic accident in 2000.

In 2009, I first came across an electric scooter in Hawaii. It was very convenient and impressive, and I decided that I would definitely buy one once I returned to Japan. However, electric scooters were not for sale in Japan that you could load and unload from your car on your own.

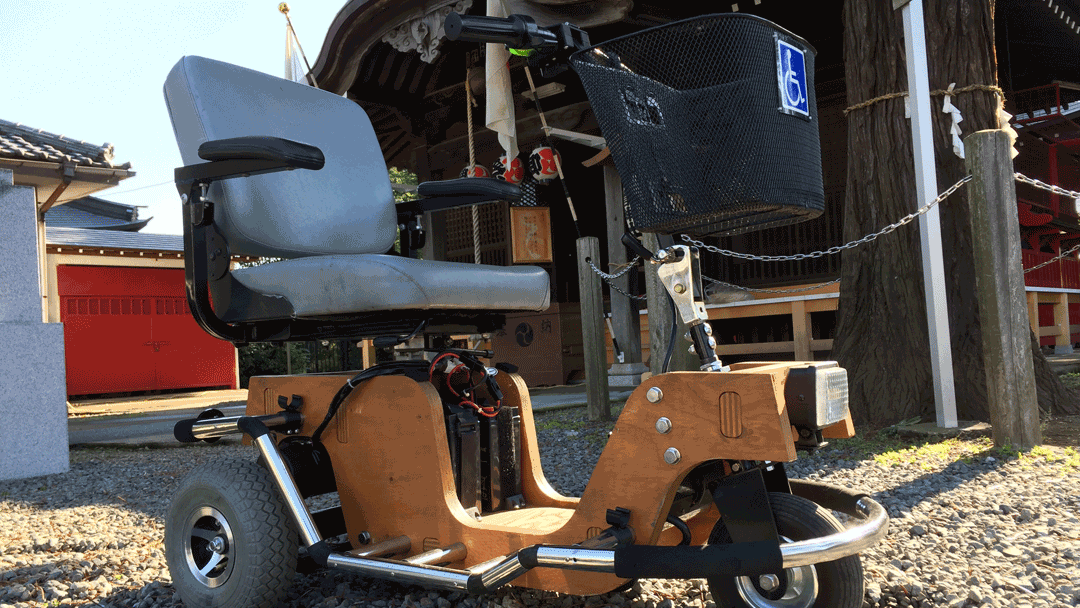

In December 2013, I read and was impressed by "FabLife" that was written by Professor Hiroya Tanaka, and I resolved to dedicate the rest of my life to Fab. In July 2014, I saw the photos and video of the ”Open Source Fab City Car Project” workshop at the Fab10 (the 10th International FabLab Conference) held in Barcelona. I was convinced that if I used plywood I could make an electric scooter myself. A mold would not be necessary. I immediately started to design it, while with 123D Design I realized the image of the electric scooter that I had thought of. The first version was completed in October 2015. It took about a year from the start of the design. Since I was able to complete it with the cooperation of FabLab, I named this electric scooter "Fab Scooter." It was made in FabLab.

On my own, I can load and unload this Fab Scooter from my car. And I can also go anywhere with this Fab Scooter.

All of the scooter body design was done on my own.

I imported the differential unit with motor, controller and setting software, wheels and tires from Taiwan thanks to Mr. Ted (FabLab Taipei) and Mr. Nick (Horng yinn co., LTD.). The plywood body was cut with a ShopBot in the professor Tanaka’s laboratory in Keio University. All the metal structures were cut and prepared by myself and brought to FabLab Hamamatsu, where Mr. Takemura helped me with the welding. The seat and handle were taken from an old scooter that I got online as well as bolts, nuts, stainless steel pipes, and casters. The rest of the parts which were not for sale anywhere such as: pipe-joint, control box and my crutch holders were made by myself with my 3D printer (Cube3). I also made the motor-controller, the control-panel wiring, board in the control box, battery gauge and USB charging port. The throttle lever unit was also remodeled to a more recent model using a 3D-printer.

Kyle Li

Kyle Li

Inspired by Hiroya Tanaka’s book, FabLife, the creator embarks on a quest to create a scooter to address his needs and the needs shared by many others. What I love about this piece is that the creator started out with no backgrounds in digital fabrication. With determination and self-motivation, the creator was able to build a firm mobile scooter from the ground up with plywood and loose parts. Maker projects like this are what keep maker movement rocking hard!